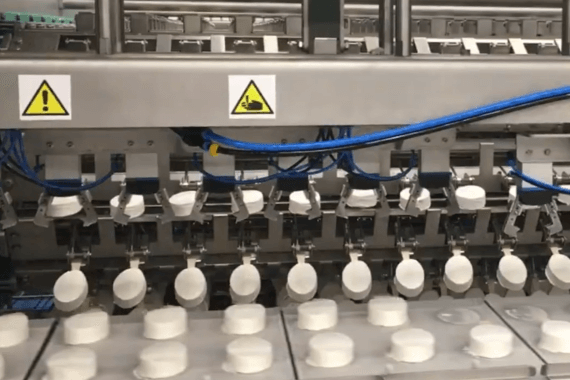

Churning moments of pure joy

At Savoy, we believe in turning simple ingredients into extraordinary ice cream. Our process is a carefully crafted blend of art and innovation, from sourcing the best raw materials to mixing, chilling, and shaping each scoop.

This is ice cream the Savoy way - crafted with care, checked for quality, and delivered with happiness in every scoop.